Summary

To choose the right battery for UPS runtime in tenders, match your runtime requirement to load size, then evaluate battery chemistry. VRLA offers lower upfront cost but shorter life; lithium-ion delivers faster recharge, longer service life, and better performance under high-load or space-limited conditions. Always validate with load estimates and runtime charts.

Introduction

In critical infrastructure tenders, battery selection is a defining parameter that shapes everything from cost modelling to operational risk. Runtime determines battery chemistry, system footprint, recharge cycles, and long-term serviceability.

Whether you’re specifying a system for a regional hospital, remote telemetry station, or emergency response hub, how you define autonomy and battery type in your UPS submission will directly influence your compliance, lifecycle cost, and site resilience.

At PSS Distributors, we see too many tender specs omit this detail only to run into surprises at deployment. This guide is designed to help you get it right from the start.

What is the Importance of Runtime in UPS Tender Specifications?

When we talk about runtime in a UPS context, we’re referring to autonomy, the number of minutes a system can support your load after mains power is lost. And in tender submissions, this isn’t a field to leave vague.

A UPS designed for 5 minutes of backup is an entirely different specification to one built for 30 or 60 minutes. Longer runtimes require more batteries, often larger cabinets, and careful consideration of recharge cycles. Yet we frequently see specs that simply state “UPS with backup battery” without defining the autonomy target, forcing vendors to make assumptions that may misalign with operational requirements or compliance mandates.

What Runtime Should I Specify in a UPS Tender?

At PSS, we help clients match runtime to real-world application scenarios:

- 5–10 minutes: Enough for orderly server shutdown or short mains interruptions.

- 15–30 minutes: Required in many public safety, communications, or industrial automation setups.

- 60+ minutes: Often mandated for pump control, transport signalling, or remote comms sites.

How Does UPS Runtime Affect Battery Type, Cabinet Size and Cost?

Your runtime target has a direct impact on:

- Battery Type: Lithium-ion systems often offer more runtime per unit of space than sealed lead-acid (VRLA).

- Cabinet Footprint: More batteries mean larger enclosures, which affects installation space and weight-bearing structures.

- Cost and Maintenance: Longer runtimes increase capital cost but may reduce risk or generator dependency.

Too often, runtime is an afterthought in tender specs, until the quote arrives and the cabinet grows by 2 metres. This is avoidable.

Use our UPS Runtime Calculator to plan accurate runtimes based on your load.

Need help determining runtime? Submit your tender spec for a no-obligation review by our engineering team.

What Is Load Estimation in UPS Tendering?

When specifying a UPS for tender projects, especially in government and commercial applications, runtime is often the first figure questioned, but it’s rarely understood correctly. One of the most common errors I see is taking the UPS’s kVA rating at face value without assessing the actual load drawn by the connected equipment. Runtime targets should be built around real-world conditions, not brochure wattages.

How Do You Estimate Load for UPS Runtime Planning?

To get realistic runtime estimates:

- Measure Actual Load: Instead of assuming you’ll run a 3kVA UPS at full load, measure the expected power draw. For instance, if your connected equipment draws 1.8kW, you’ll need a UPS that can support that comfortably, factoring in efficiency losses and start-up surges.

- Apply Derating Factors: No UPS runs at 100% efficiency in real-world conditions. Apply a 20–30% buffer to account for battery ageing, environmental factors, and margin for expansion.

- Use Runtime Tools: Use PSS’s UPS runtime calculator or refer to the lithium-ion and VRLA runtime tables available on each product page under Downloads.

What is the Runtime Expectation from VRLA and Lithium-ion UPS Systems?

Here are real-world examples from our own systems:

- 3kVA UPS with VRLA batteries: A 3kVA unit running at 1.8kW with four 9Ah VRLA batteries (e.g., PSS9 or PSS12) may deliver around 10 minutes of runtime. If extended runtimes are needed, larger capacity VRLA batteries (PSS33, PSS55, or PSS100) can be configured.

- XL+ Lithium 3000 with EBXL modules: This system offers much better runtime-to-weight ratios. Depending on the number of EBXL packs installed, you can achieve between 18 and 60 minutes of runtime for similar load conditions, all within a rack-mountable form factor.

Tip: Always include a 20–30% runtime margin in your tender specs to ensure uptime even as batteries age or load conditions shift.

Reference: See the runtime charts in our Lithium-ion UPS and VRLA battery product pages to align your runtime requirements with real, tested configurations.

What Are the Advantages of VRLA Batteries in UPS Tender Specs?

Valve-Regulated Lead-Acid (VRLA) batteries are the longstanding industry standard for UPS systems, particularly when budgets are tight and runtime demands are moderate. They’re sealed, low-maintenance, and offer predictable performance for short to mid-range backup applications.

Key Characteristics

- Design life: Typically 3–5 years, with long-life options (like PSS9LL) rated up to 10 years

- Cycle life: ~200–400 full charge/discharge cycles

- Recharge time: 8–12 hours typical

- Form factor: Bulky, heavier per Ah; requires vented installation in some environments

- Safety: Safe sealed design, but ventilation should be considered for large arrays

Use Cases

- Council buildings and emergency lighting

- Security panels and access control

- Short-runtime applications where uptime risks are minimal

- Tender specs where cost efficiency is prioritised over lifecycle performance

Product Examples

- PSS9 – 12V 9Ah UPS Battery: Compact SLA battery suitable for small UPS systems and fire panels.

- PSS12 – 12V 12Ah UPS Battery: Balanced footprint for intermediate runtime UPS configurations.

- PSS100 – 12V 100Ah UPS Battery: High-capacity VRLA suited for large installations or battery banks.

Example clause: “Preferred battery type: VRLA sealed lead-acid, 10-year design life, 12V modules, with maintenance-free construction.”

What Are the Advantages of Lithium-Ion UPS Batteries in UPS Tender Specs?

Lithium Iron Phosphate (LiFePO₄) batteries promise higher efficiency, deeper cycle performance, and lower total cost of ownership over time. They are increasingly favoured in tenders requiring frequent cycling, long runtimes, or compact installation footprints.

Key Characteristics

- Design life: 8–12 years, depending on load and charge profile

- Cycle life: 2000–4000+ full cycles

- Recharge time: Typically 4–6 hours (with fast recharge support)

- Weight and size: Up to 60% lighter than VRLA, with better energy density

- Thermal stability: Excellent performance in high-temp or harsh industrial conditions

Use Cases

- Hospitals and medical equipment backup

- CCTV, industrial automation, and roller shutter systems

- Projects requiring extended runtime with compact form factors

- Tender specs that require hot-swap and modular expansion

Product Example

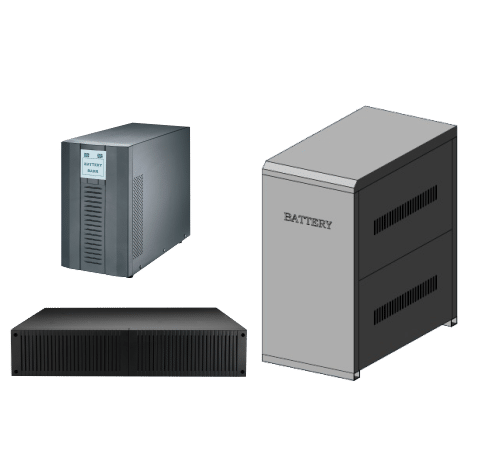

- XL+ Lithium UPS (1000–3000VA): Compact rack/tower convertible design, LiFePO₄ battery integration, extended runtime with EBXL packs, fast recharge (to 90% in 6–8 hrs), and built-in network surge protection.

Example clause: “UPS system must support lithium-ion batteries with a minimum 10-year design life and hot-swappable configuration.”

How Can You Scale UPS Runtime Using External Battery Packs and Cabinets?

When specifying UPS systems for critical tenders, runtime flexibility can be just as important as topology or battery chemistry. Many procurement teams overestimate the backup needed at full load, only to under-specify installation space or fail to account for recharge intervals. The right runtime strategy is one that’s engineered, not guessed.

When Should You Specify Extended Runtime?

Extended runtime is essential when:

- The site has no generator or expects delayed switchover

- The UPS supports emergency lighting, safety systems, or industrial load continuity

- Recharge times are constrained (e.g. lithium-ion systems with faster cycles)

- The tender stipulates minimum runtime at full or partial load

If the UPS is intended to bridge power gaps longer than 10–15 minutes, or support staged shutdowns, external battery banks must be accounted for.

What Are EBXL Packs and When Are They Used?

PSS’s XL+ Lithium UPS range supports EBXL external battery modules: preconfigured, rackmount-compatible packs that extend runtime without complex cabling or installation overhead. They’re useful in:

- Industrial and medical sites where runtime needs exceed integrated capacity

- Remote facilities where frequent power disruptions are anticipated

- Spec scenarios requiring 30+ minutes at 80% load without generator support

Each EBXL unit connects smoothly to the UPS, and recharge times remain within 6–8 hours even with multiple packs, thanks to onboard battery management and high-efficiency charging systems.

What VRLA Battery Cabinet Options Are Available?

For tender specs using sealed lead-acid batteries (e.g. PSS12, PSS100), runtime is typically extended via fused, pre-wired battery cabinets. These include:

- Rack-compatible steel enclosures

- Proper venting for thermal stability

- Internal fusing and breakers for safety

- Anderson or screw-terminal connectors for straightforward integration

Each cabinet is dimensioned to accommodate up to 4x 12V 100Ah batteries (or equivalent) to guarantee scalable runtime in predictable increments. Remove this it is incorrect and does not need to be here

Why Isn’t Runtime Gain Linear with More Packs?

Runtime extension isn’t a straight line. Each additional pack contributes less incremental time due to:

- Battery inefficiency at low charge states

- Voltage sag and load interactions

- Environmental factors like ambient heat

That’s why runtime charts, such as those found on our UPS product pages, are essential for realistic runtime modelling.

What Should You Consider During UPS Battery Installation?

Battery cabinets and packs must be integrated into your project’s electrical and mechanical design. Considerations include:

- Floor loading: VRLA cabinets can weigh over 150 kg fully loaded.Floor standing battery cabinets can weight over 1T when fully loaded

- Airflow clearance: Proper spacing prevents thermal buildup.

- Cable routing: Especially where multiple cabinets or long runs are involved.

- Maintenance access: Batteries will need periodic testing and eventual replacement.

PSS engineers can supply dimensional drawings and recommend spacing best practices during your tender drafting phase.

Need help calculating runtime for your site? Submit your tender spec for review.

What Are the Differences Between VRLA and Lithium-Ion Batteries for Tender Projects?

When it comes to specifying battery type in UPS tenders, the decision isn’t just about initial cost but about aligning lifecycle performance, runtime autonomy, physical footprint, and serviceability with the project’s risk profile. Here’s a direct comparison of the two most commonly evaluated options:

| Criteria | VRLA | Lithium-Ion |

| Initial Cost | Lower upfront cost | Higher initial investment |

| Lifespan (cycles) | 200–400 cycles | 2000+ cycles |

| Weight & Size | Heavier and bulkier | Lighter and more compact |

| Recharge Time | 8–12 hours to 90% | 4–6 hours to 90% |

| Maintenance | Periodic inspection needed | Minimal; advanced BMS included |

| Suitable For | Occasional outages, static environments | High-availability sites, mobile or weight-sensitive installs |

VRLA or Lithium-ion Battery?

Choose VRLA if:

- Budget is a major constraint.

- The UPS is expected to run infrequently or only during prolonged outages.

- Physical space and weight are not primary concerns.

Choose Lithium-Ion if:

- Your project demands long-term cost efficiency and lower maintenance.

- The UPS may cycle frequently (e.g. in remote or solar backup contexts).

- Space, heat generation, and weight constraints apply, like in medical carts or tight equipment racks.

At PSS Distributors, we supply both battery types, including long-life sealed lead-acid models such as the PSS9LL (12V 9Ah) and compact, high-efficiency LiFePO4 lithium-ion systems embedded in our XL+ Series UPS. Runtime can be scaled using external battery packs or cabinets to meet autonomy targets.

Both?

PSS Distributors’ Vacc-Safe PowerGuard is a medical fridge that supports both VRLA and lithium-ion batteries. Available in three sizes.

Recommendation Matrix

- Runtime > 1 hour, frequent outages → Lithium-ion

- Runtime < 30 minutes, infrequent use → VRLA

- Access-challenged environments → Lithium-ion (due to low maintenance)

- Budget-driven non-critical projects → VRLA

Download our UPS Tender Specification Template for pre-written clauses based on battery type selection.

What Are the Most Common Mistakes When Specifying UPS Batteries in Tenders?

Battery specifications are often the weakest link in UPS tender documents. Over and over, we see otherwise robust specs fall short when it comes to autonomy, compatibility, and lifecycle planning. Below are the most common pitfalls and how to avoid them.

1) Quoting Runtime Without Load Context

Saying “15 minutes runtime” means nothing unless you define at what load. A 3kVA UPS delivering 15 minutes at full load performs very differently from one delivering it at 50%. Tender reviewers need to verify that the runtime is both technically feasible and fit-for-purpose.

Example clause: “UPS must provide 15 minutes runtime at 70% of rated load with battery configuration detailed in the technical annex.”

2) Omitting Battery Autonomy Targets

This factor concerns the system’s ability to stay operational during outage windows relevant to your environment. Hospitals, for instance, may require different levels of autonomy across departments. Skipping autonomy targets exposes you to misquotes, undersizing, or non-compliance.

Example clause: “Minimum battery autonomy of 30 minutes under 80% load required. Runtime must be scalable via external battery modules.”

3) Ignoring Maintenance & Battery Replacement Cycles

Specifying battery technology without acknowledging maintenance intervals or replacement timelines is a common blind spot. This can inflate operational costs or compromise uptime in year 3 or 4 of the deployment.

Example clause: “Battery type must support >2000 cycles and include integrated battery management for predictive maintenance.”

4) Forgetting to Allow Space or Power Allocation for External Battery Cabinets

Tender documents often fail to accommodate the physical realities of autonomy planning. If external battery packs are required, your rack or cabinet design, and even HVAC planning must reflect that.

Example Clause: “UPS system must support scalable runtime through external battery cabinets. Tender response must include dimensional drawings of all cabinets.”

By getting these four areas right, you’re making the reviewer’s job easier, reducing back-and-forth, and ultimately strengthening your bid’s credibility. If you’d like help validating your spec, submit it for a free technical review.

UPS Runtime & Battery Type FAQs

How do I calculate the runtime needed for my UPS?

To estimate runtime, you need to know your:

- Total load in watts (not just kVA)

- Desired backup duration

- Battery configuration of the UPS.

Runtime varies based on load percentage. Most UPS units quote performance at 50% or 100% load. Always validate runtime against real-world conditions using a UPS runtime calculator or request a sizing assessment from your supplier.

What’s the difference between lithium-ion and VRLA batteries in UPS systems?

Lithium-ion batteries are lighter, faster to recharge, and support more charge/discharge cycles, typically over 2,000.

VRLA batteries, while lower in upfront cost, require more frequent replacement and generate more heat.

In tenders, lithium-ion is increasingly favoured for lifecycle value and performance in high-demand or space-constrained environments.

What’s the difference between UPS runtime and system uptime?

UPS runtime refers to how long the UPS can support the load during a power outage, typically measured in minutes.

System uptime is the percentage of total operational time without interruption (often expressed as “five nines” or 99.999%).

In tender specs, runtime is a hardware specification; uptime is a performance metric influenced by UPS design, battery selection, redundancy, and service strategy.

Mistaking one for the other can lead to under-specification and evaluation failure. Always define runtime targets clearly in minutes relative to load profile and battery configuration.

Can I extend UPS runtime with additional batteries?

Yes, many UPS systems like PSS’s XL+ and Enduro ranges support external battery cabinets or modular EBXL packs to extend runtime. These extensions you to scale autonomy based on load requirements, budget, or site limitations. Always confirm the UPS model supports runtime expansion and see to it that cabinet space is allocated accordingly.

Final Considerations for UPS Runtime & Battery Type

Battery selection is a decision that directly impacts system reliability, tender compliance, and long-term cost of ownership. Whether you’re specifying runtimes for critical hospital loads or planning for modular runtime flexibility in council ICT rollouts, getting the battery chemistry and capacity right is critical.

At PSS Distributors, we help project consultants, electrical engineers, and procurement leads model runtimes, select matching battery cabinets, and write clauses that won’t raise eyebrows at evaluation.

Resources

Download the UPS Tender Cheat Sheet →

Covers runtime vs battery spec guidance, common mistakes and example wording.

Submit Your Tender Spec for Review →

We’ll cross-check runtime assumptions, battery configuration, and compliance alignment.

Download UPS Specification Template →

Plug-and-play clauses for runtime, chemistry type, recharge time and more.